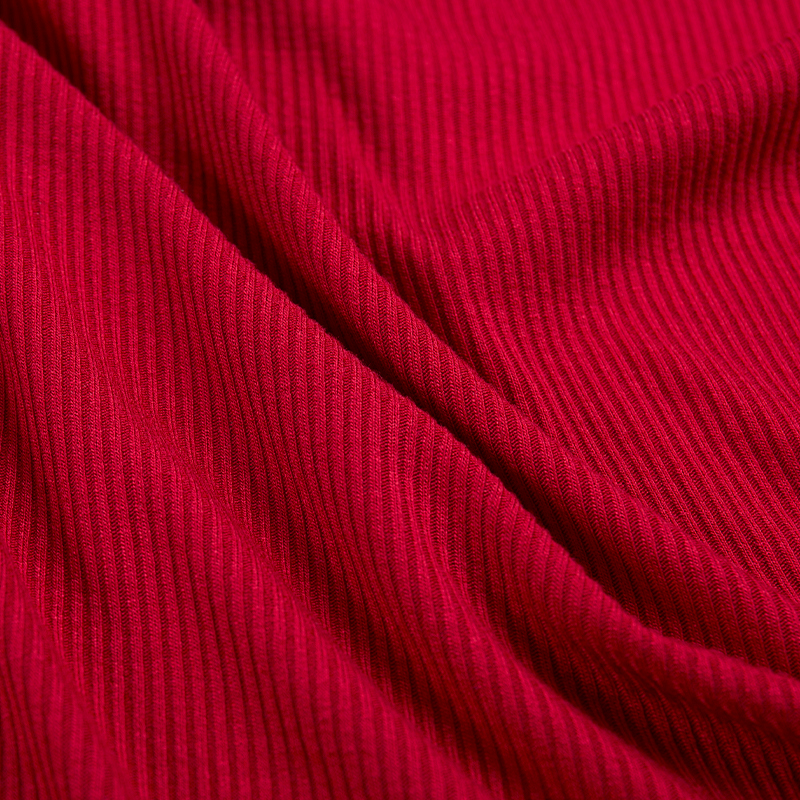

2×2 Eco-Friendly Modal Spandex Rib Knit Fabric (92% Rayon / 8% Spandex)

Product description:

This 2×2 Eco-Friendly Modal Spandex Rib Knit Fabric is crafted with a premium blend of 92% modal (regenerated cellulose fiber) and 8% spandex, combining the softness and sustainability of natural-origin fibers with the stretch and recovery of spandex. The fabric features a 2×2 rib knit structure, delivering excellent elasticity, shape retention, and a smooth, comfortable hand feel.

With a fabric weight of 200GSM and a width of 180cm, this material offers a balanced thickness—lightweight yet substantial enough to provide body support without feeling bulky. The generous width allows for efficient cutting and reduced fabric waste during garment production.

The modal fiber is derived from sustainably sourced wood pulp, making it an environmentally friendly alternative to synthetic fibers. It offers a silky-smooth texture, exceptional breathability, and excellent moisture-wicking properties, keeping the skin dry and comfortable during wear. Unlike traditional rayon or viscose, modal is more durable, less prone to pilling, and maintains its shape better over time.

The 8% spandex delivers strong two-way stretch and over 90% shape recovery, enabling the fabric to conform comfortably to the body while resisting deformation after repeated use and washing. This makes it ideal for garments requiring flexibility and dimensional stability, such as intimate apparel, loungewear, children’s clothing, sweatshirts, and activewear.

The 2×2 rib construction enhances both horizontal and vertical stretch, improving fit and comfort. Its subtle textured surface adds visual depth and improves resistance to abrasion, helping to minimize pilling and maintain a crisp appearance even after extended use.

The fabric exhibits excellent dyeability, producing soft, rich colors with high color fastness (rated above Level 4). It is also highly wrinkle-resistant and easy to care for—retaining its smoothness after washing without the need for ironing.

As a sustainable and durable textile, this modal-spandex rib knit aligns with modern consumer values of environmental responsibility and long-term value. Its combination of comfort, performance, and eco-friendliness makes it a superior choice for fashion designers and manufacturers seeking high-quality, planet-conscious fabrics.

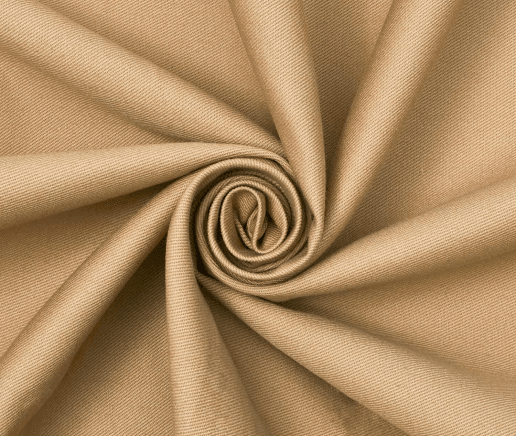

Recommended products

Shaoxing Lushuo Textile Co., Ltd. is an emerging fabric company with a history dating back to 2003. We have built our brand on 20 years of expertise in the textile industry. We are a globally recognized company and have been a leading supplier of fine knitted fabrics to the global market. As a research and development company, we are constantly developing products and strategies to meet market standards and trends.

Our company was originally founded in 2003 as Shaoxing Jiaqi Import & Export Co. Over the years, we have built a reputation for good customer service, quality materials and superior inspection standards.

-

0year

Years of experience in the industry

-

0million

Annual output value

-

0employees

Technical Engineers

-

0+

Export Country

-

A New Wave of Environmental Sustainability. Leading international rib fabric manufacturers have introduced novel materials crafted from eco-friendly substances to minimize environmental impact. These fabrics offer elastic comfort and are recyclable, spearheading the industry's green development.

see more news Oct 24 -

Facing increasingly fierce market competition, multiple rib fabric enterprises are actively expanding into international markets. By participating in global textile exhibitions and establishing overseas sales networks, these companies aim to boost exports and enhance their brands' global recognition. This strategic shift is seen as a crucial step for the rib fabric industry to adapt to globalization trends.

see more news Oct 24 -

With growing global emphasis on sustainability, the rib fabric sector is intensifying efforts to minimize environmental impact. Many companies have adopted renewable resources and recycled materials in production, alongside eco-friendly dyeing and finishing techniques. These measures not only reduce carbon footprints but also meet consumer demand for environmentally conscious products.

see more news Oct 24 -

Responding to global environmental trends, the rib fabric industry is elevating its sustainability benchmarks. New production protocols require companies to minimize wastewater discharge and energy consumption while enhancing material recyclability. These measures aim to lessen environmental impact while boosting product market appeal.

see more news Oct 24

英语

英语 西班牙语

西班牙语